Looking more like a kitchen part 1

Wainscot:

The term wainscot (pronounced UK: /ˈweɪnskət/, US: /ˈweɪnskɒt/, US dict: wān′·skət, wān′·skŏt) originally applied to high quality riven oak boards produced in medieval Poland and adjacent areas and exported to many parts of western Europe. Medieval German wageschot or ‘wall-board’.

Bead board: is a board manufactured to look like wainscot. All on a larger panel instead of individual tongue and groove pieces. Panelling.

Panelling is a wall covering constructed from rigid or semi-rigid components. These are traditionally interlocking wood, but could be plastic or other materials.

Panelling was developed in antiquity to make rooms in stone buildings more comfortable.[citation needed] The panels served to insulate the room from the cold stone. In more modern buildings, such panelling is often installed for decorative purposes. Panelling, such as wainscoting and boiserie in particular, may be extremely ornate and is particularly associated with seventeenth and eighteenth century interior design, Victorian architecture in Britain, and its international contemporaries.

The plan we had decided was a bead board style backsplash for the kitchen.

I looked for bead board and it is quite expensive. I was shocked actually.

A 32 sq/ft sheet of bead board (8×4) is $57 – ouch!

I found smaller packs and cut sizes, 7 sq/ft for $8. Only in shorter lengths though.

I cruised around the hardware store and I saw the tongue and groove pine panelling. A couple different styles. There was one style that I liked, that has more lines than a plain tongue and groove panel.

The sale: 14 sq/ft, in 8ft lengths. Reg price $9 a pack. Marked down to $6.50/pk and to top it off. There was a

Big sale for that day I went. An additional 15% off any product to a maximum of 15 pieces/packs.

So 14 sq/ft was approx $5.50

What a deal. I only needed about 4 packs, so I bought 8, lol.

We have our back splash material, now it’s time to put it all together.

If you go back to some of the older posts I made, you will see some of the styles I put up that I liked.

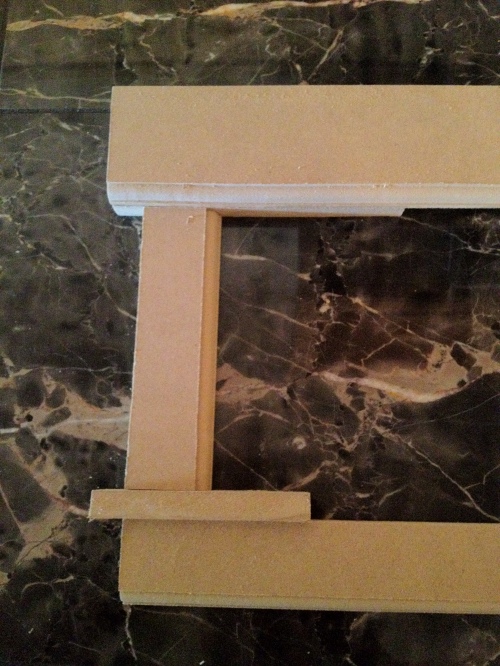

Another material I used for the back splash is 1/2″ mdf.

Mdf is very easy to work with. I had lots left over sitting in my garage from a project I did over a year ago.

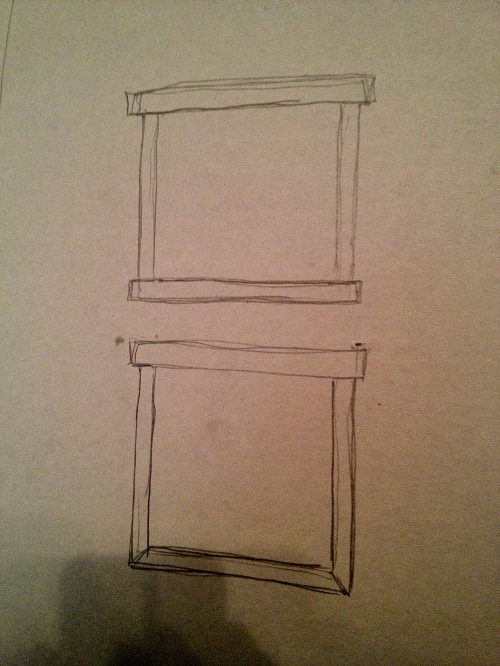

My original plan was to use this mdf to make our own trim.

The foot of the back splash will be a 2″ strip, then the pine panelling and a 1″ strip on the top to finish it off.

First I did the left side I the kitchen. Because there are no major appliances other than the fridge, I look at it as the prep area.

Then I worked on the stove side.

In order to do the stove side, I had to trim out the window and the pass through.

I had an idea of what I wanted to do, seemed a little plain.

I remembered the one window left in the house that still had the original window trim.

I pulled some inspiration from there and came up with a likable design.

On the shelves, I rounded the corners. I used the top of a spray can to trace the round corner and cut with a jig saw. Sanded smooth and we have a nice round corner.

It’s far from being finished, imagine it all painted white, even the cabinets.

We have decided to put new drywall on the ceiling now. This will give us an almost perfectly flat ceiling. Also opens up the option for crown moulding in the future.

Next step after that is to finish tape all the drywall, install the rest of the shelves, paint the cabinets and paint the walls!

This is just one more step closer to a finished kitchen!!